Threaded Rebar Couplers

Rebar couplers are used in the RCC structures to replace the system of lapping and welding in reinforcement. When there is need of long length bars or when joining the additional bars to the end of existing bars, the lapping system is applied that is the bars are tied by wire next to each over. In the same way like lapping, welding is also processed where unlike tied by wire, the bars are attached by welding.

Since, there is a wastage of bar in lapping system and welding system, an alternative system is used known as rebar coupler or the coupler in reinforcement that provides an end to end connection for the continuous reinforcement of a structure. The coupler in reinforcement is used since it is economical and cost efficient unlike the lapping system, where some part of the bar is wasted due to lapping.

The rebar coupler is particularly cost efficient for large diameter bars in the big projects of construction and construction of skyscrapers. The rebar couplers are also commonly known as mechanical splices. The rebar coupler is used in all the construction fields, such as, constructions of buildings, bridges, dams, towers, etc.

Roll Thread Rebar Coupler

In roll thread rebar coupler, the coupler is threaded by threading machine. To fit the bar in the roll thread coupler in reinforcement, the ends of the TMT bars are threaded in the Roll Thread Machine. After that the rebar coupler installation is done to the both ends of the TMT bar like nut and bolt, for the continuous reinforcement.

Cold Forged Rebar Coupler

Like the Roll Thread Rebar Coupler, the Cold Forged Rebar Coupler is also threaded by the threading machine. But in this coupler in reinforcement, the end of the TMT bar is forged by forging machine with the help of hydraulic pressure.

After the process of forging the end of TMT bar losses a minimal part of length and increases its thickness and then the bar end is threaded by the threading machine and fitted to the rebar coupler.

The cold forged rebar coupler is passed for the big infrastructure projects and other government projects. This system is passed by the Indian Government under the BIS code IS: 16172-2014.

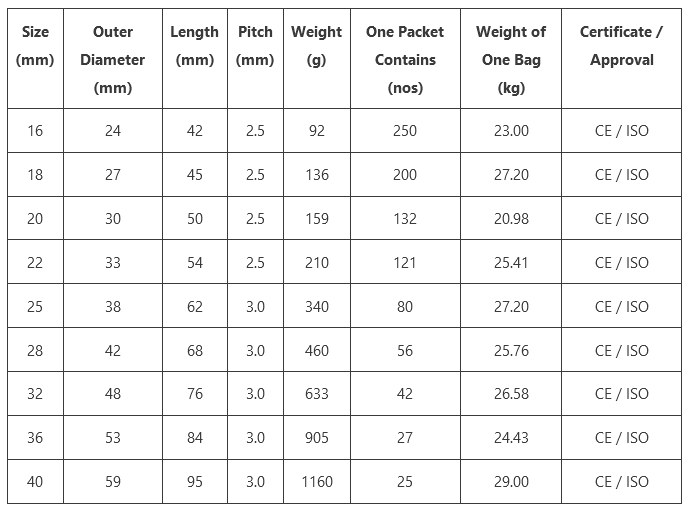

Rebar Coupler Size Chart

Like the size of the TMT bar, the TMT rebar coupler sizes comes in same, such as, 16, 18, 20, 22, 25, 28, 32, 36, 40 and so on.

Rebar Coupler Testing Procedure

A coupler in reinforcement is processed by many rebar coupler testing. Some of the test of rebar coupler are as follows:

- Cyclic Tensile Test

- Low Cycle Fatigue Test

- High Cycle Fatigue Test

- Static Tensile Test

- Yield Strength of Steel

- Slip Test

- Chemical Test

Advantages of Rebar Couplers

- The rebar coupler improves the structural integrity.

- It reduces the lapping length calculation.

- Rebar coupler increases the bar uses by not wasting bars like the lapping.

- The connection inspection is simple and easy.

- It increases work speed by quick installment.

- It is very economical amongst all the systems of joint in reinforcement.

- The load path continuity is accurate.

- The transferring of the load is proper.

- It doesn’t create congestion.

- The rebar coupler has a great quality control and easy to supervise.